Nicklon Plus (Nickel Teflon+®) Mold Release & Protective Coating

Micro Surface Corporation has been applying their Nicklon Plus (Nickel Teflon® Plus) coating in the Chicagoland/Midwest area for years to help customers improve release for Rubber Molds (Silicone, Natural Rubber, Butyl, EPDM, Prox. Cured, Nitriles, PTFE) and Thermo Plastic Molds (PolyPro, Polyethylene, PVC, Flexible PVC, Nylon, Polyurethane, K-resin).

Nicklon Plus improves release on no draft cores, cavities, deep ribs, bosses and EDM on compression or injection tooling. Outgassing corrosion and staining is generally eliminated with Nicklon Plus.

Nicklon Plus is a proven coating technology to enhance resin flow in an injection or compression mold and create an excellent release condition for either plastic resins or rubber compounds with a peroxide cure. From medical to automotive components, Nicklon Plus will improve release of all low melt plastic resins or rubber compounds and create a barrier for corrosion protection. Applied to steel, aluminum, or alloy materials Nicklon Plus has a 15 year track record of successful release of golf ball thermoplastics, medical grade polypropylene, PVC all grades, silicon rubber both grades, and other low melt thermoplastic resins and rubber compounds.

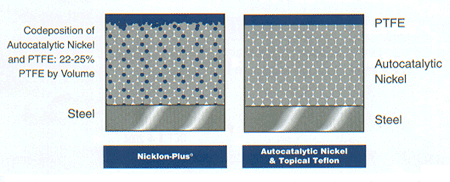

Due to the homogeneous distribution of autocatalytic nickel and PTFE, there is a continual renewal of PTFE as the mold surface sustains normal wear. PTFE topical treatments will degenerate over time as the PTFE breaks down and the topcoat wears off the mold surface.

Compared to Electroless Nickel with Boron Nitride particles (Nickel Boron), which is marketed as having good lubricity and release due its low coefficient of friction, Nicklon Plus provides superior release for molds running resins or rubber compounds because it contains FEP Teflon; the best release material DuPont ever developed. While Nickel Boron does a good job in some applications such as on weapons and gun parts, Nicklon Plus outperforms it and other coatings and surface finishes by addressing the issues of corrosion, enhanced flow of resin, release, and melt temperature of the resin or rubber compound that is molded.

Benefits of Nicklon Plus

- Improves resin flow by 4-8%.

- Creates excellent release condition on no-draft or difficult-to-eject parts and eliminates the need for mold release sprays.

- Ensures a uniform application in deep ribs, bosses and complex details.

- Extends mold life though its high corrosion resistant characteristics.

| Specification: | Data: |

|---|---|

| Composition: | Nickel 80-83% by weight, Phosphorus 9-11% by weight, PTFE 8-9% by weight (22-24% by volume) |

| Maximum Operating Temperature | 525°F |

| Thickness | 0.000050" to 0.0035" |

| Coefficient of Friction | 0.1 to 0.2 |

| Density | 6.5 to 7.5 g/cm3 |

| Hardness HVN100 | 550-600 or ap. 55-58 HRC |

| Surface Finish, Ra | 0.5 micrometers or better |

| Wear Resistance - (Sliding surfaces) | Low load/moderate speed or moderate load/low speed |

| Taber Abraser Wear - (1,000 cycles, CS-10 wheel 1,000 g. load) | 16 mg. |

| Taber Abraser Wear - (1,000 cycles, CS-10 wheel 1,000 g. load) with Heat treating at 480°F (250°C) for 6 hours | 12 mg. |

| Corrosion Resistance - ASTM B-117 at 0.5 mil | 650 hours |

| Corrosion Resistance - ASTM B-117 at 1.0 mil | 1,000 hours |