Tungsten Disulfide (WS2) Coating per AMS 2530

Tungsten Disulfide (WS2) is a low friction dry lubricant coating that improves performance and service life better than other coatings by reducing friction & noise, improving mold release, and solving problems of excessive wear, seizing, galling and fretting. The coating is applied with pressurized air that impinges the dry metallic coating without heat, binders or adhesives and makes it bond instantly to any metal or resin substrate with a thickness of 0.00002" (1/2 micron).

For nearly 40 years Micro Surface Corporation, located an hour outside of Chicago, IL has applied the Tungsten Disulfide (WS2) low friction coating to the AMS2530 & DOD-L-85645 standards. Please contact us for a quote, turnaround time is generally 3-5 days after receipt of customer components.

Benefits and Capabilities of Tungsten Disulfide (WS2)

- Tungsten Disulfide (WS2) overcomes or reduces mechanical lubrication problems which improve performance and extend service life.

- Reduces friction to lower emissions as less fuel or battery energy is used for a given power level when applied to engine parts such as pistons rings, cams and bores.

- Can reduce the frequency of maintenance problems that cause breakdowns and expensive downtime by stopping galling, fretting and friction caused by dissimilar metals and their different hardness factors.

- Maintains the dimensional integrity of the substrate to within 1/2 micron with no build-up. Tungsten Disulfide (WS2) particles will not adhere to themselves so the coating thickness is limited to 1/2 micron.

- Withstands loads to 100,000 psi (or load capacity equal to substrate) and operates in the temperature range of -460°F to 1200°F (-273°C to 650°C).

- Offers 100% lubricity throughout its texture and contains no binders or PFAS.

- Is inert, non-toxic, non-distortive, non-corrosive and resistant to most fuels and solvents. It is compatible with and enhances the performance of all oils and greases.

- Resists carbon build-up due to its extremely low co-efficient of friction, less than half that of graphite, Moly (MoS2) and Teflon.

- Molecularly bonds to all materials and platings and can only be eliminated by removing the bonded substrate.

- No bakeout or heat curing is required for the application of the coating.

How does Tungsten Disulfide reduce friction?

Tungsten Disulfide reduces friction and increases the life of components by eliminating the cold welding that takes place when two metal surfaces meet and start to rub against each other.

Low Coefficient of Friction

Tungsten Disulfide (WS2) achieves a dynamic coefficient of .030 and static .070 to .090. Pressure, surface finish and surface hardness will effect these results. Extensive real time, real life wear indicates little change over time unless severe overload conditions are introduced.

Compatibility

WS2 is used successfully with petrochemical oils and greases, synthetic oils, silicone lubricants and hydraulic fluids. It has an affinity for lubricants and strives to maintain a hydro dynamic layer.

Coating Thickness

Tungsten Disulfide (WS2) is 0.00002 in. (1/2 micron) thick and its inherent molecular shape and particle size prevent it from building thicker. The coating is blue-gray in color and will mirror back all the characteristics of the substrate.

Chemical Stability

Tungsten Disulfide (WS2) is inert, non-toxic, non-corrosive, and contains no PFAS. WS2 can be applied to all stable metal substrates. It is impervious to most solvents, refined fuels, and chlorinated solvents. It is attacked by fluorine gasses, sulfuric and hydrofluoric acids and hot, caustic alkaline solutions. WS2 is resistant to corrosion but cannot inhibit the effect of corrosion on inherently low resistance materials.

High Operating Temperature

WS2 operates from -460°F to 1200°F in normal atmosphere and 2400°F in a vacuum. Above 800°F when heated in air there is an oxidation threshold that will cause it to slowly decompose to tungsten oxide. Out-gassing characteristics are quite low too. Tungsten Disfulides ability to withstand high temperatures makes it excellent for bolts, studs, and shafts that are used in engine exhaust systems of all types of vehicles. Tungsten Disulfide is very stable at high temperatures in gas atmospheres such as nitrogen and argon. Thermogravimetric testing in argon at 2552°F showed a max of 0.2% weight loss after four hours and similiarly lost less than 0.2% loss by weight when heated to 2552°F in a nitrogen atmosphere and at temperatures up to 3362°F remained essentially unchanged.

| Specification: | Data: |

|---|---|

| Thickness | 0.00002" |

| Coefficient of Friction: | 0.03 - 0.09 |

| Operating Temperature: | -460°F - 1,200°F |

| Color: | Blue / Grey |

| Food Contact: | No |

| Hardness: | Please see below |

| Cure Temperature: | None |

| Load Capacity: | 100,000 psi |

| Chemical Stability: | Inert, Non-Toxic |

| Appliable To: | Any Metal or Resin |

| Release Performance: | Excellent |

| Friction Reduction: | Excellent |

| Molecular Weight: | 248.02 |

| Absolute Densisty, g/cm3: | 7.4 |

NASA Publication with Micro Surface:

Tungsten Disulfide combination coatings for additional wear & corrosion protection.

- Chrome or Electroless Nickel with Tungsten Disulfide (WS2)

- Provides additional wear protection from the 70Rc hardness of the chrome or EN and the low friction of Tungsten Disulfide.

- Anodizing with Tungsten Disulfide (WS2)

- Provides aluminum with more corrosion and wear protection with low friction from Tungsten Disulfide.

- Chromium Nitride (CrN) combined with Tungsten Disulfide (WS2).

- The thin hard coating of PVD applied CrN combined with Tungsten Disulfide provides a thin hard film with a very low friction factor which address stamping tooling and wear components in assembly and packaging machines.

Tungsten Disulfide (WS2) Care Instructions:

Tungsten Disulfide (WS2) is a durable coating and normally injection molds do not need to be recoated for approximately one year. Glass filled or talc filled resins of 30% or more will reduce the life of the coating because of their abrasive nature. To protect your coated mold components:

- Cleaning solvents such as acetone, mineral spirits or alcohol can be used with no adverse affects. Strong alkaline solutions or acids cannot be used as they will remove the coating.

- Tungsten Disulfide (WS2) is compatible with all mold saver type products. We do recommend that a corrosion protector be used on molding surfaces during storage.

Component Parts and Assemblies that benefit from Tungsten Disulfide (WS2)

- Bearings

- Tungsten Disulfide (WS2) is an excellent coating for bearings where conventional lubricants can not be used or where the application requires the insurance of a permanent lubricant for extended wear life as in gear motors or transmissions. From miniature bearings used in dental hand pieces to large bearings for electrical power plants, the coating is excellent at extending wear life. MSC recently completed testing on bearings which showed Tungsten Disulfide (WS2) coated bearings lasted much longer and endured more rigorous testing conditions than the uncoated bearings while requiring a significantly lower level of torque and ran at a lower operating temperature.

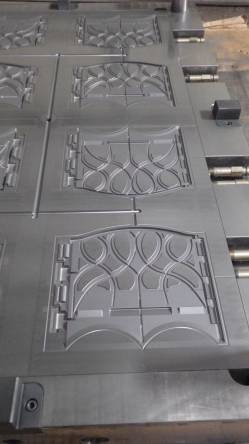

- Injection Mold Tooling

- All mold components that contact resin such as slides, gibs, and inserts benefit from improved resin flow and mold release of 3 to 9% and increased productivity from 4 to 8% on average. It does not transfer to finished parts and provides longer lasting release than alternitives such as mold spray.

- Automotive Components

- Automotive components such as engine and rod bearings as well as transmission and differential parts and CV joints have lower friction which results in longer wear life, reduced squeaking and noise, better gas milage and reduced fuel costs by requiring less energy.

- Gears

- Gears for a number of devices benefit from lower friction and longer wear life such as those used in clean rooms, automotive transmissions, rear end differentials, high load heavy equipment, and generators.

- Acme or Ball Screws

- Ball screws coated with Tungsten Disulfide run smoother from having lower friction and as a result will have longer life.

- Shafts

- Shafts coated with WS2 have longer life because they run smoother with less friction. Common applications are in motor drives, spline shafts, acme screws, and turbine engines.

- Wear Plates

- Wear Plates are able to function at high temperatures with a lower coefficient of friction extending wear life.

- Chain

- Chain coated with Tungsten Disulfide is able to run without wet lubrication and also benefit from lower friction.

- Valve Stems

- Tungsten Disulfide coated valves benefit from lower friction and in turn longer wear life which is beneficial in automotive fuel injection systems, diesel hydraulic systems, ball and metering valves, and nuclear systems.

- Hardware

- Steel, stainless steel, or titanium bolts, screws, nuts, and fasteners have lower friction making it easier to assemble and disassemble & also prevents galling.

- Cutting Tools

- Cutting Tools coated with Tungsten Disulfide provide a better surface finish and have a longer wear life.

AMS2530 / DOD-L-85645 Tungsten Disulfide (WS2) Application Process:

AMS2530 is the aerospace material specification that outlines the application of Tungsten Disulfide (WS2) thin lubrication film coating in a binder less impingement applied method that does not require a curing process. Tungsten Disulfide (WS2) has historically been used on metal components and some non-metallic items such as thermoplastics and thermosetting polymers where an extremely thin coating of 1/2 micron in thickness is needed to reduce friction, wear, galling, seizing, and fretting.

- Raw Material: Must be finely powdered Tungsten Disulfide (WS2) free from contaminants such as graphite, molybdenum disulfide, binders or other materials so as to be compatible in liquid oxygen systems and hard radiation environments. Micro Surface uses the highest quality North American sourced and USA produced Tungsten Disulfide (WS2) in its coating application.

- Cleaning: Prior to application the components to be coated must be thouroughly cleaned to remove all external substances such as oils, greases, dirt as well as any oxidation and must be handled to prevent re-contamination during the coating process.

- Application:Tungsten Disulfide (WS2) is impinged on the component at ambient temperature.

- Adhesion Verification: Micro Surface Corp. verifies the adhesion of Tungsten Disulfide (WS2) by using a pressure sensitive film backed tape that is applied to the sample and rapidly removed in accordance with ASTM D 2510 to confirm that no flakes or particles of the coating are removed exposing the base metal.

- Thickness: The thickness must be less than or equal to 0.00002 inch (0.5 micron).

- Thermal Stability: The coating must be able to withstand temperatures in the range of -300°F to 900°F.

- Appearance: The coating color must be a uniform silver gray color that does not have cracks, pinholes, blisters, or other surface imperfections when viewed under a microscope.

- Corrosion Resistance: Anodized aluminum panels must not show signs of discoloration or pitting after 500 hours of exposure from ASTM D 2649 testing.

- Quality: Parts are inspected to ensure proper application, adhesion, & appearance. The coating must be uniform in color, smooth and free from surface imperfections.

Spiral Flow & Mold Release Improvement with Tungsten Disulfide (WS2)

A sprial flow study conducted by Western Washington University showed improvements of 3% to 9% in resin flow after being coated. The study was conducted to quantify flow enhancement afforded by the Tungsten Disulfide (WS2) coating when applied to injection, blow and extrusion molding/tooling. This return on investment to customers is experienced in improved product quality due to reduced operating pressure and temperatures, as well as significantly lower operating costs resulting from faster cycling and increased tool life.

| Resin | Uncoated (in.) | WS2 Coated (in.) | % Increase |

|---|---|---|---|

| Polypropylene Amoco 4039B | 45.7 | 47.2 | 3.3% |

| ABS Monsanto M0648 | 41.1 | 42.4 | 3.2% |

| Acetal Delrin II 900NC | 39.3 | 41.1 | 4.6% |

| Polyethylene DC 10262B | 38.7 | 40.2 | 3.9% |

| Polycarbonate DC 301 | 35.5 | 36.7 | 3.4% |

| PETG Eastman 6763 | 29.7 | 32.4 | 9.1% |

| Acrylic RH 811 | 26.9 | 27.9 | 3.7% |

| Impact Styrene DC 478WB | 26.1 | 26.9 | 3.1% |

| Crystal Syrene DC 685 | 25.4 | 27.5 | 8.3% |

| Ultem 1000 (300F Mold Temp) | 19.5 | 20.5 | 5.1% |

Tungsten Disulfide (WS2) Coating History

Today only dimly remembered by space enthusiasts and not at all by the general public, the Mariner missions of the 1960s and 1970s constituted one of the most successful of all NASA programs in the early days of U.S. space research. The Mariners were a family of spacecraft for studies of Venus and Mars. There were nine of them; three failed during or shortly after launch, but the others scored spectacular successes for their day. Launched in 1962, Mariner 2 passed within 10,000 miles of Venus and became the first successful planetary probe. Mariner 4 (1964), a Mars explorer, was the first spacecraft to return pictures of another planet. Mariner 5 (1967) made the second U.S. flyby of Venus, closer this time at 2,500 miles from the planet's surface. Mariners 6 and 7 (1969-76) flew within 2,000 miles of Mars and provided some 200 pictures. Mariner 9, launched in 1971, went into orbit around Mars, sent thousands of photos of the red planet and its moons, and mapped one third of the martian surface. The Mariners were developed in a period of rapidly advancing technology, so each model contained some improvements over its predecessor. The last four, Mariners 6 through 9, represented a second generation of the family, larger, heavier and considerably more sophisticated than the earlier spacecraft. These latter Mariners incorporated a great deal of what was then considered leading edge technology: A variety of advances in on-board power, scientific instrumentation, communications and imaging/data transmission systems. Among all these improvements was an unsung technology: a dry film lubricant designed to meet the special needs of Mariner missions. Developed for NASA by Dr. Robert D. Nelson of Stanford University, it offered exceptional lubrication quality for reduced friction and extended wearlife of mating parts operating in harsh interplanetary environments where temperatures ranged from well below zero to 500 degrees Fahrenheit.

The technology was subsequently acquired and refined by Micro Surface Corporation and in 1984 introduced Tungsten Disulfide (WS2) to general industry and it has since compiled an excellent performance record in an ever-widening range of applications among the automotive, medical equipment, plastics, tool and die, and robotics industries. It has been used, for example, to coat machine tools, industrial gears and bearings, electric motors, compressors, and cryogenic pumps. In the plastics industry, Tungsten Disulfide (WS2) users have found that in some operations, such as blow molding, injection molding and extrusions, the coating increases production by reducing the drag between tool steel and resin. In automotive and racing applications, it is used to reduce friction and wear in such components as auto bearings, transmissions and engine internal parts.

Commmon Questions and Answers about Tungsten Disulfide (WS2)

- What is the effect of temperature (thermal stability) on Tungsten Disulfide (WS2)?

- The coating is thermally stable between -460°F to +1200°F.

- How scratch resistant is Tungsten Disulfide (WS2)?

- Sharp objects can remove the coating and in harsh dusty environments the life of the coating is decreased.

- Is Tungsten Disulfide (WS2) electrically conductive?

- Yes, it is electrically conductive although in and in low voltage (mil amps) there can be some resistance.

- Is it possible to coat non-metallic surfaces such as carbon fiber, plastic, rubber, ceramic, etc with Tungsten Disulfide (WS2)?

- It is best applied on metal surfaces such as steel, aluminum, titanium, or magnesium but can be applied to carbon fiber, rubber as well as polyimide plastic retainers which had good success when coated as part of an assembled bearing. Glass and ceramics are not good candites for the coating.

- Can the thickness of Tungsten Disulfide (WS2) be maintained in mass production?

- Uniform thickness of the coating can be maintained because the material will not stick to itself.

- What surface roughness is required to achieve good adhesion with Tungsten Disulfide (WS2)?

- Surface roughness is not a factor, a clean and non-oxidized surface is the normal surface. Excellent coating adhesion can be achieved on Ra finishes as fine as 2.

- Will laser marking affect the coating color or performance of Tungsten Disulfide (WS2)?

- Laser markings will not affect the color or performance.

- What is the impact of Tungsten Disulfide (WS2) on noise and torque level?

- When applied to head tooling, gears, bearings, bushing and related components the noise level and energy consumption are reduced and spindle speeds are increased without chatter.

- Is it possible to coat a specific region like inner track, outer track and seal grooves only?

- Yes, specific areas can be coated with fixturing and masking.

- Is it advisable to coat only balls rather than coating all components? If we only coat the balls, will it cause any problem when sliding with uncoated races during application?

- The best low friction and extended wear life results have always been achieved when all matting surfaces are coated. However, only coating the balls is also done on some applications with good results. The uncoated areas do not exhibit any detrimental effects.

- Will Tungsten Disulfide (WS2) react with grease at higher temperature?

- The coating is completely compatible with all greases and oils. It is frequently used with high temperature greases in steel mills and rolling mills at aluminum plants.

- Should Tungsten Disulfide (WS2) be applied in the assembled condition or before assembly?

- The best results are achieved when individual components are coated but very good results can also be achieved on fully assembled items.

- What is the corrosion resistance of Tungsten Disulfide (WS2)?

- Unfortunately it is not a corrosion inhibiting coating, it will slow down the process but will not add any significant resistance.

- Can the coating thickness of Tungsten Disulfide (WS2) be increased? What is the relationship between coating thickness and life?

- Increasing the coating thickness is not possible and would not increase the life or functionality of the coating.

- What are the failure modes of the Tungsten Disulfide (WS2) coating, how long will it last?

- The coating can be removed with acids or high alkalines. It does not crack or peel off. In a non-abbrassive environment the coating is permanent. On an injection mold running non-abbrassive resins 24/7 it will last 12-14 months.

- I have a mold with an A2 mirror finish that makes a clear part, can Tungsten Disulfide (WS2) maintain this finish?

- Yes, it will maintain a mirror finish to produce clear parts.

- How is your process/product superior to Tungsten Disulfide (WS2) aerosol spray cans sold online? Can I apply the coating myself?

- Aerosol spray cans sold online do not provide the performance of factory applied Tungsten Disulfide (WS2). The spray cans do not provide an inert Tungsten Disulfide (WS2) because there are chemical dispersions and solvents used to keep the material in suspension. These chemical contaminants are deposited on the surface of the parts trying to be coated and therefore deter adhesion. WS2 particles have a very high molecular weight and consequently will settle in solvents and not flow evenly. The chemical additives reduce and lower the temperature range both on the top end as well as at the bottom end. Most solvents used in aerosol cans boil off at very low temperatures and do not work well at sub-freezing temperatures either. Adhesion of the Tungsten Disulfide (WS2) particles cannot take place with an aerosol spray technique because of the nature of the material. The coating was developed for NASA and requires a very detailed protocol and process to achieve adhesion on all substrates. Lawrence Livermore Laboratory, Lockheed, and NASA aerospace engineers with the assistance of University research staff spent years developing the techniques, protocols and processes that are used by Micro Surface.

- How hard is Tungsten Disulfide (WS2)?

- Since the coating is impinged into the substrate its being applied to and is so thin (less than 1 micron), it will have the same hardness as the material its being applied to. If you require a harder surface we can apply it over Hardcoat Anodize, Chromium Nitride (CrN), Electroless Nickel, or Chrome.

- Is Tungsten Disulfide safe?

- Yes, it is completely inert, non-toxic, and contains no PFAS.

- How is Tungsten Disulfide coating applied?

- It is applied by impinging the coating into the substrate by using pressurized air.

- How thick is Tungsten Disulfide coating?

- The coating is 0.00002" (1/2 micron) thick.