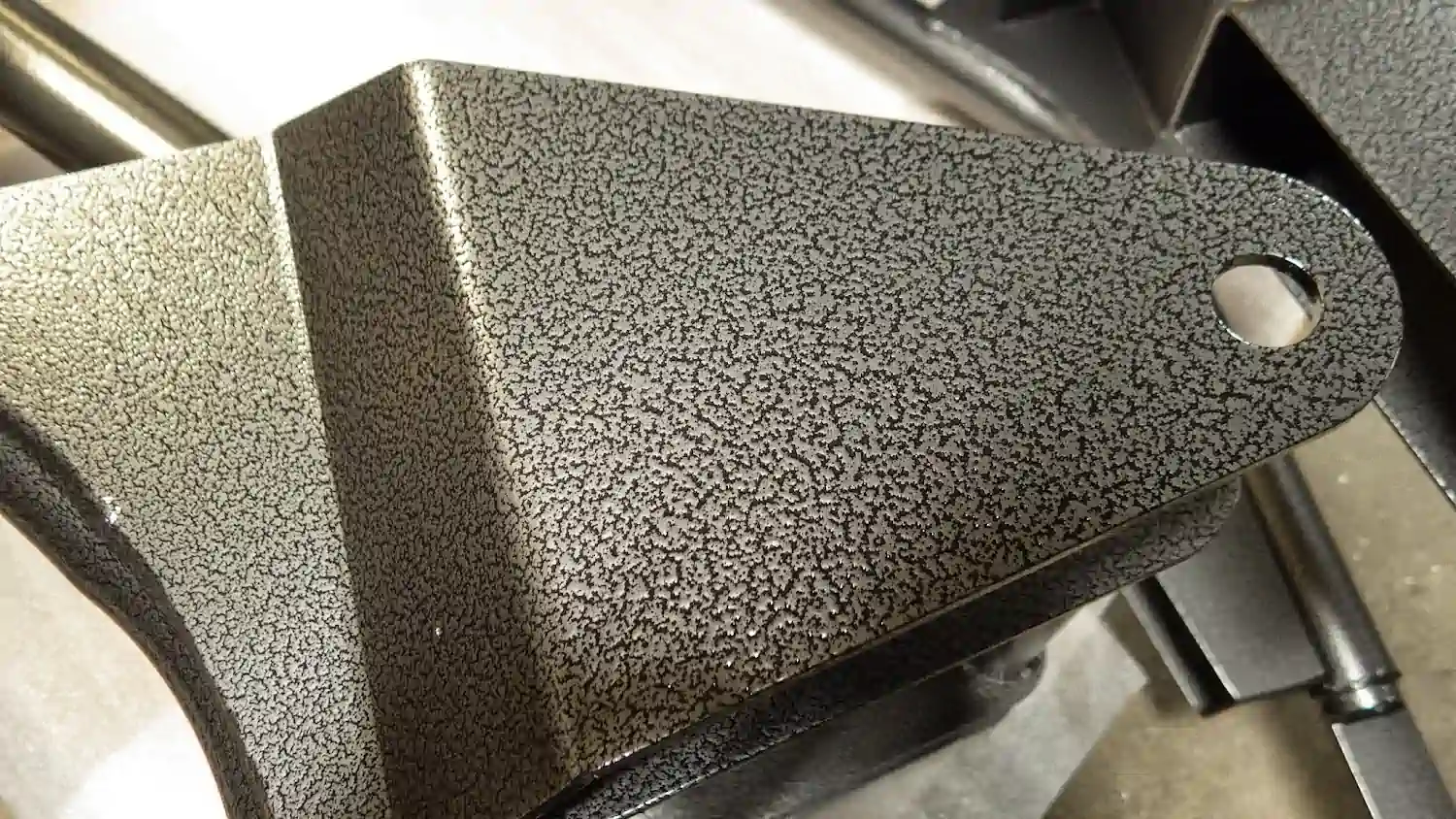

Powder Coating Service

Micro Surface Corporation has provided high quality powder coating services for customers in the Chicago area and throughout the USA for more than 30 years. Powder Coating is more durable than traditional liquid paints and provides excellent corrosion protection, improves the material surface finish appearance of metal products, act as an UV protectant, and even has some non-stick applications. We stock powder in a range of colors from Tiger Drylac, Sherwin Williams, TCI, and Americoats. We can process parts up to 12ft x 10ft x 10ft and can handle customer orders with complex masking requirements. Our variety of guns and ovens allow us to be flexible and attentive to your needs to produce a top-quality finish. Our experienced applicators and 2 shifts give us the ability to give you a quick turnaround time so that you can meet your production schedules. Please contact us for a quote, turnaround time is generally 3-5 days after receipt of customer components.

Powder Coating Process:

- Cleaning: Parts are cleaned to remove all oil, grease & other substances. Cast parts are de-gassed.

- Pretreatment: Parts are pretreated via media blasting to ensure proper adhesion.

- Application: The coating is sprayed onto the item either manually or on one our automated production lines.

- Cure / Bake: The part is cured in an oven at a temperature from 350°F to 400°F.

- Inspection: Parts are inspected to ensure proper application.

| Property | Epoxy | Epoxy / Polyester Hybrid | Polyester | Urethane | Acrylic |

|---|---|---|---|---|---|

| Weatherability | |||||

| Corrosion Resistance | |||||

| Chemical Resistance | |||||

| Heat Resistance | |||||

| Impact Resistance | |||||

| Hardness | |||||

| Flexibility | |||||

| Adhesion |